Truck Stabilizing Jacks Help Improve Dock Area Safety

A common concern of any architectural specifier or building owner is loading dock safety. Loading docks which receive large amounts of traffic are especially prone to accidents and injuries. By supplying your loading dock with the correct safety equipment, you can greatly reduce the risk for accidents at the loading dock, as well as improving overall efficiency. One type of equipment is the trailer jack stand, which, when paired with other safety equipment, increases dock safety significantly.

Preventing Accidents Due to Trailer Creep

One common type of preventable accident-causing occurrence is trailer creep. Trailer creep is caused by fork trucks repeatedly entering and exiting the trailer, slowly causing the trailer to become separated from the dock leveler. If left unchecked, this could cause injuries and even deaths to the forklift operator or other workers. There are several variables that can affect trailer creep, including the weight of the fork truck with its load, suspension softness, type of loading dock crossing such as a dock leveler or dock board, as well as a lack of connection between the trailer and the tractor.

Though historically wheel chocks have been used to prevent this phenomenon, several things must be considered, such as wheel chocks slipping and the necessity of workers walking between trailers to set chocks. Wheel chocks and truck restraints can help reduce the chances of trucks accidentally rolling away during loading and unloading.

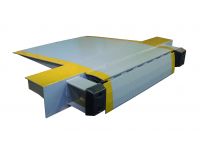

Preventing Trailer Upending with Trailer Jack Stands

A more reliable addition to wheel chocks at loading docks is a trailer jack stands stabilizer. They are useful for supporting a trailer’s front end when not connected to the truck at a dock. Truck stabilizing jacks help prevent trailer upending which occurs when a detached trailer tilting its front end down and rear end up, potentially harming any dock workers that are in, around, or crossing into the trailer. OSHA 1910.178(m)(7) requires the uses of chocks and sometimes trailer jacks when trailers are unattached to tractors.

Trailer upending can be caused by the trailer’s landing gear collapsing, often due to rust damage or metal fatigue. By securely supporting the trailer with a trailer jack stand in addition to wheel chocks and even manual or hydraulic truck restraints, the possibility of this type of loading dock accident is greatly reduced.

It is often recommended to use a trailer jack in the front two trailer corners. When a truck backs up to your dock, you have no idea how old it is, and subsequently how old the nose legs are. Over time, nose legs become weaker and weaker. When a forklift driver enters the trailer at full speed and drops the payload at the front of the trailer, there is a chance of the nose legs collapsing and injuring the fork truck operator and anyone else nearby.

Choosing the Correct Trailer Jack for Specific Applications

Several aspects must be considered when choosing a truck jack for your loading dock. Firstly, what kind of portability is required? Jacks with wheels reduce worker strain by eliminating the need to manually carry them. An extremely important consideration is the static and lifting capacity—how heavy is the trailer with the fork truck, payload, and dock workers inside?

Another considerable factor is what type of operating mechanism each trailer jack has. Common options include ratchet beam, hydraulic beam, hand crank, spin top, ratchet, and economy models. Finally, many different models with varying service ranges are available. How many inches must the trailer be raised in order to be level with the loading dock?

In conclusion, by combining various types of equipment, such as truck restraints, trailer jacks, wheel chocks, traffic signal dock lights, loading dock spotlights, and dock barricades, you can help reduce the risk of workplace accidents. Many different types of dock safety equipment is available in order to help you run the most safe and efficient loading dock possible.

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 12 Products

Browse 12 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 8 Products

Browse 8 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 9 Products

Browse 9 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products