Wooden and Plastic Pallets Are Designed For Efficient Shipping and Storage

Pallets are an important piece of shipping equipment that can be found in many industrial buildings and warehouses. Every year, roughly two billion shipping pallets plastic – metal are used in just the United States. When cargo arrives, it is often shipped on a pallet or skids then secured with stretch wrapping. Pallets are then moved around the warehouse, distribution center, or loading dock, sometimes stacked, by pallet trucks or fork trucks using their fork slots.

Pallet Types

Pallets can be made out of a variety of materials for different applications. All pallets fall under two general categories—stringer pallets, which have only parallel “stringers” or frame pieces, and block pallets, which use perpendicular and parallel stringers for added strength.

Among the most common type of pallet is the wooden pallet. Softwood pallets and nestable wood pallets made from pressed wood are the most economical option, while hardwood models are often sturdier. Paper pallets can be used for light loads and are both economical and environmentally friendly.

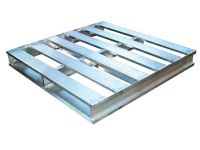

Plastic pallets are generally stackable, can be washed down, and are chemical resistant. Plastic pallets are available in two types: recycled ACM (Advanced Composite Material) suitable for one-way applications or recycled or virgin PE (Polyethylene) for multi-trip use. Metal pallets are another option when extra durability is required. Unlike wooden pallets, they are resistant to bugs, do not get splinters, and can be recycled and kept sanitary.

Single-Use and Reusable Pallets

Pallets are further divided into two more categories: single-use (one-way) or reusable (two-way or closed-loop). Softwood and paper pallets are generally designed to be disposed of once the cargo reaches its destination. Hardwood pallets may be reused, but eventually can break apart with dangerous nails or splinters exposed.

Plastic pallets can be designed for export applications where the pallet is not returned, but it may be reused by the receiving company. Closed-loop pallets are designed to be used and reused and are often used in situations where the same customer that receives the pallet also ships it back.

Specific Applications

The wide range of pallet types are utilized by an even wider range of industries: grocery, dairy, beverage, chemical, drums, automotive, retail, and military, among others. A standard pallet size in the United States is the 48” wide by 40” long pallet, closely followed by 42” by 42” and 48” by 48” pallets. Square pallets are better resistant to tipping due to a heavy load.

Wooden pallets, unless treated properly according to APHIS international standards, are not generally used for import and export applications due to their ability to harbor insects or bacteria such as E. coli.

Plastic pallets are ideal for use in chemical industries because of their resistance to corrosion and ability to be washed down and sanitized. They are also highly durable. However, they are not recommended for long-time storage because they suffer from plastic creep, deformation caused by holding loads for long times.

Steel and aluminum pallets are designed for heavy-duty loads, but are less common than other models due to their higher initial cost. However, because of their long life and ability to be used many times, they can end up with a lower overall cost than wooden or plastic pallets that must be replaced.

Stainless steel models are ideal for use in clean rooms. Aluminum units are often used for military transport because they are lighter than steel and resist corrosion, rotting, and weather. They are therefore excellent for use in air-freight, outdoor storage, and sea applications.

Make sure to verify that the pallets you use conform to the correct ISO Standards or any other applicable codes.

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 12 Products

Browse 12 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 8 Products

Browse 8 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 9 Products

Browse 9 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products