In today’s marketplace, the movement of goods by freight is an integral part in a company’s continued success. According to the United States Department of Transportation, 60 percent of the $98.6 billion of freight moved in May 2013 between the U.S., Canada and Mexico was transported by trucks with shipments by rail trailing in second at 15 percent. With as much business being done by these methods in so many different parts of the country, there isn’t always the convenient opportunity to offload goods at a loading dock. Some situations might even require products to be moved in the field, whether to be delivered or transferred to another vehicle. Even when a permanent loading dock is available, height differences in truck bed heights might necessitate the use of a leveling device to accommodate them.

In many of these instances, a yard ramp is the optimal solution: it is cheaper than installing a permanent loading dock, provides a backup in case of issues with dock leveler system, is easily moved to accommodate forklifts and can even be implemented for use during periods of high traffic or on temporary job sites. Their mobility also makes them a boon for smaller areas where space is limited.

Types of Yard Ramps

Some yard ramps loading dock are designed for operating in specific conditions or roles. For example, a railcar loading ramp is made to withstand a significant amount of weight with a dynamic range between 16,000 and 60,000 pounds supported by heavy duty welded steel construction. Usually between 30 and 36 feet in length, they need to bridge the gap between the rail car and ground for easy access.

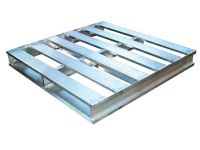

More lightweight than their steel brothers, the aluminum yard ramp is able to be maneuvered into place by one person and directly attached to the rear of trucks, trailers and other vehicles. These ramps are rust resistant and most useful in weather conditions where temperatures are well below freezing or in coastal areas where salt air can have adverse effects on steel ramps.

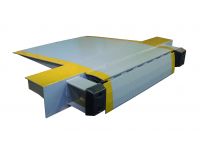

If necessary, an edge of dock leveler could also be necessary. It is a combination unit made of steel with self-supporting, stationary legs that allow it to assume the load of the yard ramp instead of vehicle suspension. Trucks and reverse up to it as they would a traditional concrete loading dock.

Steel Yard Ramps

The most commonly found on job sites, steel yard ramps are extremely versatile in their application, with a number of features that make them appealing to any industrial facility. Positive traction open steel grating gives fork lift trucks the grip to carry heavy loads with ease, while four inch high safety curbs prevent rolling or tipping over the sides of the ramp. Optional tow packages can also be included that grant greater mobility and even high towing speeds up to 45 mph.

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 12 Products

Browse 12 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 8 Products

Browse 8 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 9 Products

Browse 9 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products