Across the United States, businesses are designing their loading and unloading procedures in a number of different ways. Some are making products for markets across the globe, requiring them to set up shipping networks through large, multi-loading dock door centers and facilities known as distribution centers, or DC’s. Others may only utilize a couple of loading docks to receive materials, or even no dock at all depending on its scope of operation, such as at a manufacturing facility or construction site. Regardless of function, a Beacon product exists to assist with any loading and unloading procedures for your intended applications.

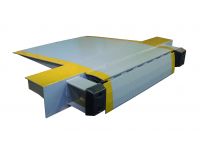

Even when loading docks are constructed to accommodate standard tractor trailer bed heights, some uneven gap differences can occur when vehicles back up to the dock face. Dock Levelers are designed and manufactured to be installed as an integral part of the building. Handling goods and materials across these spaces can lead to potential injuries, disrupting the work flow process and diminishing productivity. Taking measures to provide adequate loading systems for personnel will save on the costs associated with these problems down the road. Dock levelers are an ideal piece of equipment for mitigating such occurrences and keeping a facility running with optimum safety and efficiency.

The Beacon brand of dock levelers are made with a heavy duty welded structural steel construction and can give your facility decades of service if used according to owner’s manuals and preventative maintenance agreements. Beacon can also provide some assistance for correct equipment installation. Available with manual or push button hydraulic controls, levelers are lowered and raised to serve as a connecting platform to and from the dock platform. This enables forklifts and hand trucks to roll quickly and easily between the truck and dock.

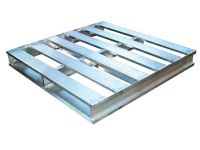

In instances where a loading dock is not available, like at outdoor job sites, a yard ramp can be used to facilitate loading and unloading procedures in the field. Typically, a yard ramp is attached directly to the rear of a truck or rail car door with the lip resting on the vehicle bed. This takes the load off of the ramp legs and transfers it to the truck’s suspension. A stationary, dock yard ramp can be installed at facilities for those who only require quick ground access. When an edge of dock leveler is attached to these units, self-supporting legs assume the weight to prevent vehicles from doing so.

The addition of tires and tow attachments allow workers to quickly move or position ramps when needed. Aluminum yard ramps are more lightweight than steel, making them manageable enough for one employee to handle, but also suited for sale air environment to help prevent rust. Whether as a standalone, portable unit or installed as a fixed ramp, Beacon models can also be optioned with additional features such as safety curbs, hand rails or forklift side pickup slots.

When weighing the benefits of dock levelers vs. yard ramps, speak with a Beacon expert to ensure your equipment is rated for its intended capacity, duty cycle and has the correct dimensions.

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 12 Products

Browse 12 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 8 Products

Browse 8 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 9 Products

Browse 9 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products