In “Unwrapping the Packaging Industry,” a 2013 study by business advisory firm Ernst & Young, the global consumer packaging market is estimated to be worth around $400 billion, with a value of $500 billion if industrial end-markets are included. From textiles to industrial appliances, companies today are always looking to make up lost dollars due to inefficiencies in their production lines. Henry Ford kick started an industrial revolution when he first implemented his moving assembly line in 1913 to meet the growing demand for the Model T automobile. Luckily, the modernization of factories and introduction of new technologies have eased the strain off of human operators. This changeover to semi-automated processes have increased output and cut costs from the long term bottom line for businesses willing to update their internal framework.

The culmination of the assembly line is packaging and preparing goods for shipment to their intended markets. Packaging equipment is employed across many industries as a major component of their shipping departments. Choosing the right equipment to maximize the efficient use of material is a decision that could potentially save thousands of dollars in operating costs.

Types of Packaging Equipment

For companies that produce large amounts of smaller, loose products, containment during shipping is needed to prevent damage to goods during transit. As the demand for these products require them to be distributed worldwide, the need for more durable packaging arises. Items like polypropylene strapping are designed to protect items by absorbing the shock of loading and unloading in addition to being made with a uniform texture to maintain structural integrity and resist splitting. These are then loaded from spools onto semi-automatic strapping machines which dispense the material around a box or shipping pallet then tightens and joins the ends with a secure heat weld. Steel strapping provides the strongest support for the most demanding conditions. Edge protectors can also be fitted at the corners of loads to stabilize them during shipping and prevent damage caused by straps digging or cutting into tightly wrapped cargo. These are made from steel, nylon or plastic.

Stretch Wrapper

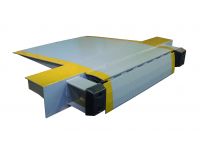

The Beacon BSWA series of automatic stretch wrapper machines feed a highly stretchable plastic film that binds together items and secures them with elastic force. They can be used to bundle pallet loads or groups of smaller items. The material to be packaged is set on the 48 inch diameter treadplate deck of the powered carousel, capable of holding up to 5,000 pounds. Meanwhile, the film is dispensed as the carousel rotates from a rod attached to a counter balanced mast that can be raised or lowered via foot pedal control. Approach ramps can also be attached to ease loading onto electric or manual pallet trucks, as well as scales for determining the weight of loads.

Whether packing manually or by machine, a variety of packaging equipment shrink wrap products are available to quickly increase productivity in your shipping and packaging area while saving wasted dollars.

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 12 Products

Browse 12 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 8 Products

Browse 8 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 12 Products

Browse 12 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products