The most prominent workplace safety challenge in this country is the prevention of back injuries. Costing industries to the tune of billions of dollars every year, these injuries make up one-fourth of all employee compensation claims and bring pain and anguish to around one million workers each year according to the Bureau of Labor Statistics. While OSHA recognizes that total elimination of back injuries is a challenging target to reach, a significant amount of these occurrences can be prevented through an “effective control program and ergonomic design of work tasks.”

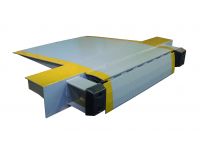

One such way is the suggested use of mechanical aids such as pneumatic lifts, conveyors or any equipment that can automate the handling of industrial or commercial materials. Most industrial Tilt Tables are designed to minimize worker fatigue and injuries by placing work materials within ergonomically proper reach of personnel. The installation of this equipment can dramatically reduce repetitive stress injuries while also increasing worker output.

Types of Lift and Tilt Tables

Lift and tilt tables can be produced in a variety of configurations that include single scissor lift, slide deck, or hydraulic cylinder designs. They can be powered air and electrical hydraulics, mechanical air systems, or even manually by a worker. While some are designed to rest on the factory floor, smaller tilters can be attached to work benches, table tops and even mobile lift tables for easy positioning. Most lift and tilt tables rotate and are constructed from heavy duty steel in order to endure a high frequency of lifting high capacity payloads such as pallets, crates and baskets full of heavy materials. The right lift and tilt table can be found for just about any workshop or factory floor plan.

Hydraulic Tilt Tables

The Beacon BHTT series is heavy duty in design and can handle load capacities of a whopping six thousand pounds. The smooth steel top platform is available in sizes up to 120-inches square. Lifetime self-lubricating, anti-friction bearings sit on all pivot points of the unit to not only provide smooth operation, but allow companies to get full, uninterrupted use over the life of the product. Anchor grab claws or chains can also be provided to keep payloads from shifting and possibly injuring operating personnel.

The electric hydraulic tilt table systems in this unit are powered by a motor pump reservoir. This works an internal, high pressure gear pump complete with a check valve, relief valve, pressure compensated flow control valve, as well as suction and return filters that make this a highly efficient, ergonomic piece of equipment for any work station.

Lift and tilt tables provide cost-effective health and safety benefits for employers through enhanced and consistent productivity, reduction in training replacement works and limiting liability. Cutting the risks of manual handling of materials can also be a boon for workers who are often exposed to the possibility of injury or ill health.

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 12 Products

Browse 12 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 8 Products

Browse 8 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 12 Products

Browse 12 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products