As an essential element of the world’s economy, manufacturing facilities see many of the goods bought and sold today pass through their doors. Loading docks make up a lot of real estate in these facilities, marking them as a very important point of contact in the global supply chain. From the extremely large, multiple loading dock door facilities to the rudimentary docks of a small business, the safety concerns in these areas remain very similar.

According to Material Handling & Logistics magazine, fatalities and serious injuries at loading docks occur more frequently when there is “unwanted separation between the trailer or truck being loaded and the loading dock. In these incidents, forklift operators are the ones most susceptible to danger. Their forklift can potentially drive off the dock during premature pull away, harming the driver and damaging goods. It is not uncommon for situations to occur where the forklift and driver are still in the truck trailer when it departs from the loading dock. Of the 96 deaths that occurred at loading docks between 2002 and 2009, 11 of those were due to separation between the trailer and dock.

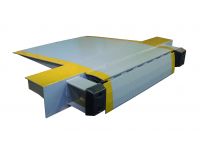

One of the many products that help to reduce the risk of accidents at the loading dock are vehicle restraints installed at the loading dock face to prevent unintended movement of a truck or trailer. A heavy duty steel hook mechanism connects to the ICC bar to minimize trailer creep during loading and unloading procedures, or even premature vehicle pull away. Truck restraints are often used in addition to other pieces of loading dock equipment. Using wheel chocks in conjunction with a dock restraint system further promotes the safety of loading dock workers.

Traffic dock signal lights mounted on the dock wall inside and outside the dock door allow inside personnel know when they can enter a trailer and also truck drivers are disengaged and free to depart from the dock. For manual truck restraint loading dock safety, dock signal lights are available as automatic or manually operated. Electric truck restraints come standard with signal lights. Driver warning signs posted near these red and green traffic lights instruct both the dock worker and truck driver in safety procedures at the dock.

The more popular and cost effective option for many businesses, the BMVR series of manual trailer restraints utilize a push rod from the dock worker while standing at the top of the dock to engage and disengage the restraint hook. Compact in design, these units boast some of the smallest body profiles in the industry, mitigating the risk of equipment damage. The heavy-duty steel, all weather frame make this model a durable and practical piece of equipment for your loading dock.

The Bear Claw BEVR650 series of automatic electric dock truck restraints feature a convenient push button control panel to engage and disengage the hook. Rated with a 50,000 pound restraining force, these units are anchored on the front dock wall face with no concrete or pit work required at installation. A 4 inch thick dock bumpers are recommended for optimum projection performance. Installing this vehicle restraint system not only enhances dock safety, but may also lead to lower insurance premiums for some customers. You may want to call your insurance sales rep that handles the insurance building policy to contact the insurance underwriter and see how you qualify.

Browse 10 Products

Browse 10 Products Browse 20 Products

Browse 20 Products Browse 19 Products

Browse 19 Products Browse 17 Products

Browse 17 Products Browse 10 Products

Browse 10 Products Browse 12 Products

Browse 12 Products Browse 6 Products

Browse 6 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 5 Products

Browse 5 Products Browse 9 Products

Browse 9 Products Browse 8 Products

Browse 8 Products Browse 23 Products

Browse 23 Products

Browse 2 Products

Browse 2 Products Browse 5 Products

Browse 5 Products Browse 3 Products

Browse 3 Products Browse 2 Products

Browse 2 Products Browse 7 Products

Browse 7 Products

Browse 6 Products

Browse 6 Products Browse 8 Products

Browse 8 Products

Browse 3 Products

Browse 3 Products

Browse 14 Products

Browse 14 Products Browse 11 Products

Browse 11 Products Browse 13 Products

Browse 13 Products Browse 8 Products

Browse 8 Products Browse 5 Products

Browse 5 Products Browse 13 Products

Browse 13 Products Browse 35 Products

Browse 35 Products Browse 4 Products

Browse 4 Products Browse 13 Products

Browse 13 Products

Browse 13 Products

Browse 13 Products Browse 21 Products

Browse 21 Products Browse 12 Products

Browse 12 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products

Browse 6 Products

Browse 6 Products Browse 12 Products

Browse 12 Products Browse 2 Products

Browse 2 Products Browse 17 Products

Browse 17 Products Browse 3 Products

Browse 3 Products Browse 12 Products

Browse 12 Products Browse 7 Products

Browse 7 Products Browse 14 Products

Browse 14 Products Browse 39 Products

Browse 39 Products Browse 4 Products

Browse 4 Products Browse 14 Products

Browse 14 Products Browse 20 Products

Browse 20 Products Browse 4 Products

Browse 4 Products Browse 17 Products

Browse 17 Products Browse 4 Products

Browse 4 Products Browse 11 Products

Browse 11 Products Browse 27 Products

Browse 27 Products Browse 20 Products

Browse 20 Products Browse 29 Products

Browse 29 Products Browse 8 Products

Browse 8 Products Browse 2 Products

Browse 2 Products Browse 4 Products

Browse 4 Products Browse 28 Products

Browse 28 Products Browse 8 Products

Browse 8 Products Browse 21 Products

Browse 21 Products Browse 11 Products

Browse 11 Products Browse 9 Products

Browse 9 Products Browse 13 Products

Browse 13 Products Browse 4 Products

Browse 4 Products Browse 4 Products

Browse 4 Products Browse 16 Products

Browse 16 Products Browse 15 Products

Browse 15 Products Browse 10 Products

Browse 10 Products Browse 26 Products

Browse 26 Products Browse 3 Products

Browse 3 Products